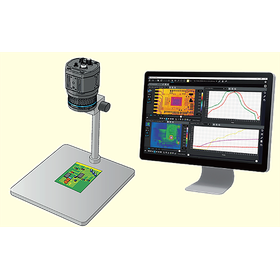

Thermography inspection system

This is a thermographic inspection system that visualizes temperature state changes in the production line and distinguishes between good and defective products.

This is a device that uses thermal images measured by a thermography camera for inspection, judgment, output, and data storage. While typical handheld thermography is intended for temporary measurements, our system enables continuous inline inspection by combining it with a compact fixed thermography camera. *Note: Not all thermography cameras are compatible; only specified models from our company can be used. The following improvements are expected as a result of implementation: - Full inspection: Automatically inspects by inputting synchronization signals from external sensors or machines. - Prevention of defective product discharge: Can detect temperature anomalies and output errors to external devices. - Traceability: Allows for follow-up verification through the storage of thermal images with data. - Data collection: Capable of collecting a large amount of temperature data that can lead to future improvements.

- Company:旭日産業 工業製品事業部

- Price:Other